450°F

Source: The 4 Types of Heat Treatment Steel Undergoes – Kloeckner Metals

Medullary Rays

Source: Oaks, Sheoaks and Medullary Rays

Australia’s first cabinetmakers, often convicts, built fine furniture that is now historically important as a record of early colonial times. Story by Jamie Bell.

Source: Historical: Colonial cabinetmakers – Australian Wood Review

This is a long and technical post because this subject is important, complex, nuanced and fun. By the end we guarantee you will have learned something new.

Source: Wood Longevity Vs. Color Longevity With Yakisugi “Shou Sugi Ban” | Nakamoto Forestry

The Salamanca Wharf Hotel is anchored on Castray Esplanade, sited between two historic Georgian sandstone warehouses.As an extension of Hobart’s renowned Salamanca Place, Castray Esplanade is enviably located in Tasmania’s single most visited tourism precinct and Hobart’s premier hospitality, entertainment and cultural hub.Castray Esplanade and Salamanca Place is a historic docks area lined with a long row of Georgian sandstone warehouses built in the 1830s. These handsome north-facing buildings once stored grain, wool, whale oil, apples and imported goods from around the world. The precinct began to take shape in the late 1820s after the number of ships carrying whale products, goods, immigrants and convicts proved too much for the Old Wharf at Hunter Street on the northern side of Sullivans Cove.The southern end of the cove possessed deeper anchorage and better shelter, and in 1830 the Government agreed to build New Wharf where Castray Esplanade and Salamanca Place now exist. New Wharf soon became one of the world’s great whaling ports and as Tasmania’s export trades increased, the need for dockside warehouses quickly grew. In 1833, John Lee Archer, one of Australia’s most renown early colonial architects, was commissioned to design new buildings to house the Ordnance stores on Castray Esplanade. The sandstone Ordnance stores would house all government supplies, both military and convict.Hundreds of convicts (housed in hulks moored at New Wharf) quarried the cliffs behind Salamanca, cut the stone and built the Ordnance stores on Castray Esplanade and the row of sandstone warehouses that face Salamanca Place.Perched on the small hill behind The Salamanca Wharf Hotel sits the original Signal Station and Mulgrave Battery, which was built in 1818 during panic about a rumoured Russian invasion. They are now part of the picturesque Princes Park, overlooked by The Salamanca Wharf Hotel. Nearby, the octagonal Tide House, next to the original Ordnance Stores, is the point from which all distances are measured in Tasmania.By the late 1800s Hobart’s whaling days were over and the New Wharf warehouses were given new life as fruit processing and jam producing factories. Tasmania’s climate was well suited to growing stone fruits and the export market for jam and processed fruit expanded rapidly in the 1890s. During the next 50 years, many Salamanca Place buildings were expanded into each other to accommodate hundreds of workers producing millions of tonnes of jam and tinned fruit for export all over the world. Jam and tinned fruit sales slowed through the 1960s, and many of the warehouses fell into a state of decline, with various buildings and floors rented out and others remaining unoccupied for years. The Ordnance stores on Castray Esplanade remained in government hands and continued to house military supplies, until it was transferred to the Postmaster General’s department in the 1950’s.Today, these wharf buildings and storehouses have been converted into a collection of restaurants, cafes, art galleries and studios, specialty shops and residences. The Salamanca Wharf Hotel has been creatively designed to sympathetically coexist as a new structure built on a vacant parcel of land between two of Castray Esplanade’s oldest and most important buildings. Reflecting the evolution of the precinct, opposite the hotel, the recently renovated Princes Wharf 1 facility is home to Tasmania’s largest annual event, the acclaimed week-long Taste Festival which attracts in excess of 250,000 patrons. Adjacent to this site, the $45 million Institute for Marine and Antarctic Studies (IMAS) is under construction and by 2013 it will house more than 300 staff and students as an extension of the CSIRO Marine Research Laboratories situated at the Battery Point end of IMAS. And every Saturday, Salamanca Place takes on a carnival atmosphere when it hosts the famous Salamanca Markets. Over 300 stallholders congregate to sell produce and crafts from all over Tasmania as buskers, artists and performers keep the crowd entertained.

Source: Salamanca, Hobart apartment accommodation – Salamanca Wharf Hotel

http://paulbourke.net/geometry/transformationprojection/

Source: Bushwalk Australia • View topic – Bluestonebay Walk – Freycinet

Myself and a group of friends did the Bluestone Bay walk on Tuesday and what a wonderful walk it is. The wildflowers were amazing and the coastal views spectacular and a walk we all recommend, however our Parks department does not seem to encourage the public to do this walk. Firstly the Bluestone Bay sign is not visible from Cape Tourville road but about 200 metres along the Bluestone Bay road itself – photo attached – and as you can see is in the new blue corporate signage used by Parks. Once you drive the 2.3KM to the end of the road – we drove a Subaru Forester with no problems – it is virtually impossible to find the start of the walk – no signs whatever – we bush bashed down the gully and up the other side until we found the well formed track. If you walk up the dry creek bed the GPS to find the start of the track is S42.10417 E148.32997.

It is sad that Parks do not open this walk up to the public in a better way, after all it is a NP for the people – I am told that the track may well be leased out to commercial operators hence the Parks reluctance to publicise

Source: Factors for Selecting the Right Stick Electrode

|

Assess Your Base Metal

The first step in choosing an electrode is to determine your base metal composition. Your goal is to match (or closely match) the electrode composition to the base metal type, which will help ensure a strong weld. If you’re in doubt about the composition of your base metal, ask yourself these questions:

If you’re working with a broken part or component, check for a coarse and grainy internal surface, which usually means the base material is a cast metal.

If the base metal is magnetic, chances are good that the base metal is carbon steel or alloy steel. If the base metal is not magnetic, the material could be manganese steel, 300 series austenitic stainless steel or a non-ferrous alloy such as aluminum, brass, copper or titanium.

As a rule of thumb, more flare in the sparks indicates a higher carbon content such as in A-36 grade steel.

A chisel will bite into a softer metal, such as mild steel or aluminum, and bounce off of harder metals, such as high carbon steel, chrome-moly or cast iron.

Tensile Strength

To prevent cracking or other weld discontinuities, match the minimum tensile strength of the electrode to the tensile strength of the base metal. You can identify a stick electrode’s tensile strength by referring to the first two digits of the AWS classification printed on the side of the electrode. For example, the number “60” on an E6011 electrode indicates that the filler metal produces a weld bead with a minimum tensile strength of 60,000 psi and, as a result, would work well with a steel of similar tensile strength.

Welding Current

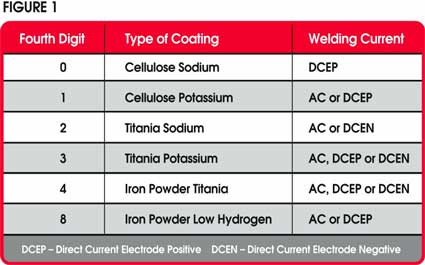

Some electrodes can be used with only AC or DC power sources while other electrodes are compatible with both. To determine the correct current type for a particular electrode, refer to the fourth digit of the AWS classification, which represents the type of coating and type of compatible welding current (see Figure 1).

|

| Refer to the fourth digit of the AWS classification to determine the compatible welding current. |

The type of current you use also influences the penetration profile of the resulting weld. For example, a DCEP compatible electrode, such as an E6010 delivers deep penetration and produces an extremely tight arc. It also has the ability to “dig” through rust, oil, paint and dirt. A DCEN compatible electrode, such as an E6012, provides mild penetration and works well when bridging two joints or welding high speed, high current fillet welds in the horizontal position.

An AC compatible electrode, such as an E6013, produces a soft arc with medium penetration and should be used to weld clean, new sheet metal.

Base Metal Thickness, Shape and Joint Fit-Up

Thick materials require an electrode with maximum ductility and low hydrogen to prevent weld cracking.Electrodes with AWS classification numbers ending in 15, 16 or 18 provide excellent low–hydrogen properties and good toughness (high impact values) to accommodate for residual stress.

For thin materials, you will need an electrode that produces soft arcs, such as a 6013, Also, smaller diameter electrodes will provide shallow penetration to help prevent burn-through on thinner materials.

You’ll also want to assess the joint design and fit-up. If you’re working on a joint with a tight fit-up or one that is not beveled, use an electrode that provides a digging arc to ensure sufficient penetration, such as an E6010 or E6011. For materials with wide root openings, select an electrode, such as an E6012, that creates a concave weld face suitable for bridging gaps and making groove welds.

Welding Position

To determine what position(s) a particular electrode is qualified for, refer to the third digit in AWS classification. Here’s how you decipher the qualified electrode position:

1 = flat, horizontal, vertical and overhead

2 = flat and horizontal only

For example, a 7018 electrode can be used in the flat, horizontal, vertical and overhead positions.

Specification and Service Conditions

Make sure to assess the conditions that the welded part will encounter throughout its service. If it will be used in high heat or low temperature environments, subjected to repetitive shock loading, a low hydrogen electrode with higher ductility will reduce the chance of weld cracking. Also, be certain to check for welding specifications if you’re working on critical applications such as pressure vessel or boiler fabrication. In most cases, these welding specifications will require you to use specific types of electrodes.

Environmental Job Conditions

To achieve the best results, you should always remove excessive mill scale, rust, moisture, paint and grease. Clean base metals help prevent porosity and increase travel speeds. If cleaning your base metal is not possible, E6010 or E6011 electrodes deliver a deep penetrating arc that has the ability to cut through contaminants.

Conclusion

Consideration of the above factors will help you overcome the challenges of selecting the correct stick electrode for your particular application. However, given the wide range of available electrodes, several solutions may exist for one application. If you need additional assistance with electrode selection, your local welding supply distributor or a company representative of a reputable filler metal manufacturer can serve as an excellent resource.